Everyone knows tractors. As kids, we saw them from car windows on cross country road trips through rural America. But these pastoral images don’t tell the whole story.

Tractors are the main cause of accidental deaths on farms, responsible for 250 fatalities annually. Over the years, many farmers, farm workers and others living on or visiting farms, have been killed or seriously injured falling from moving tractors, being run over by tractors, or being crushed when a tractor rolls sideways or backwards.

By equipping tractors and farm equipment with agricultural backup camera systems, they’re only made safer. In this article, we’ll cover the history of tractors, the most common risks, and some safety tips as well.

Tractor History

The first powered farm implements in the early 19th century were basically big portable engines on wheels that could be used to move farm machinery by way of a flexible belt. Engineer Richard Trevithick designed the first 'semi-portable' stationary steam engine for agricultural use in 1812, and it was used to drive a corn threshing machine.

The truly portable engine was invented in 1893 by William Tuxford of Boston, Lincolnshire who started manufacture of an engine built around train locomotive boilers with horizontal smoke tubes. A large flywheel was mounted on the crankshaft, and a stout leather belt was used to transfer the drive to the equipment being driven.

In the 1850s, John Fowler used a portable engine to drive apparatus in the first public demonstrations of the application of cable haulage to cultivation. In 1892, John Froelich invented and built the first gas powered tractor in Iowa. Thus, the modern tractor was born.

Tractors and other farm equipment typically have specialized tools for specific tasks. Simply put, they are powerful work horses that require training and proper care for their safe operation.

Common Safety Issues with Tractors

Anyone who uses farming equipment like tractors must understand how these vehicles work and acknowledge their inherent safety risks. Tractor manufacturers develop these vehicles for a specific purpose, therefore, anyone who attempts to use one should thoroughly understand proper operation and consult the manufacturer’s included safety warnings and instructions for use. However, some risks of tractors are unavoidable.

Farm equipment, when maintained well, can last a very long time. More than half of the tractors in use in the U.S. are older models with outdated safety features. ROPS did not become standard equipment on US-manufactured tractors in 1986. ROPS are a roll bar or cage frames that are specifically designed for tractors to protect the operator in the event that the tractor overturns. Many tractors manufactured before 1986 are still widely used on farms and unlikely to have been retrofitted with ROPS.

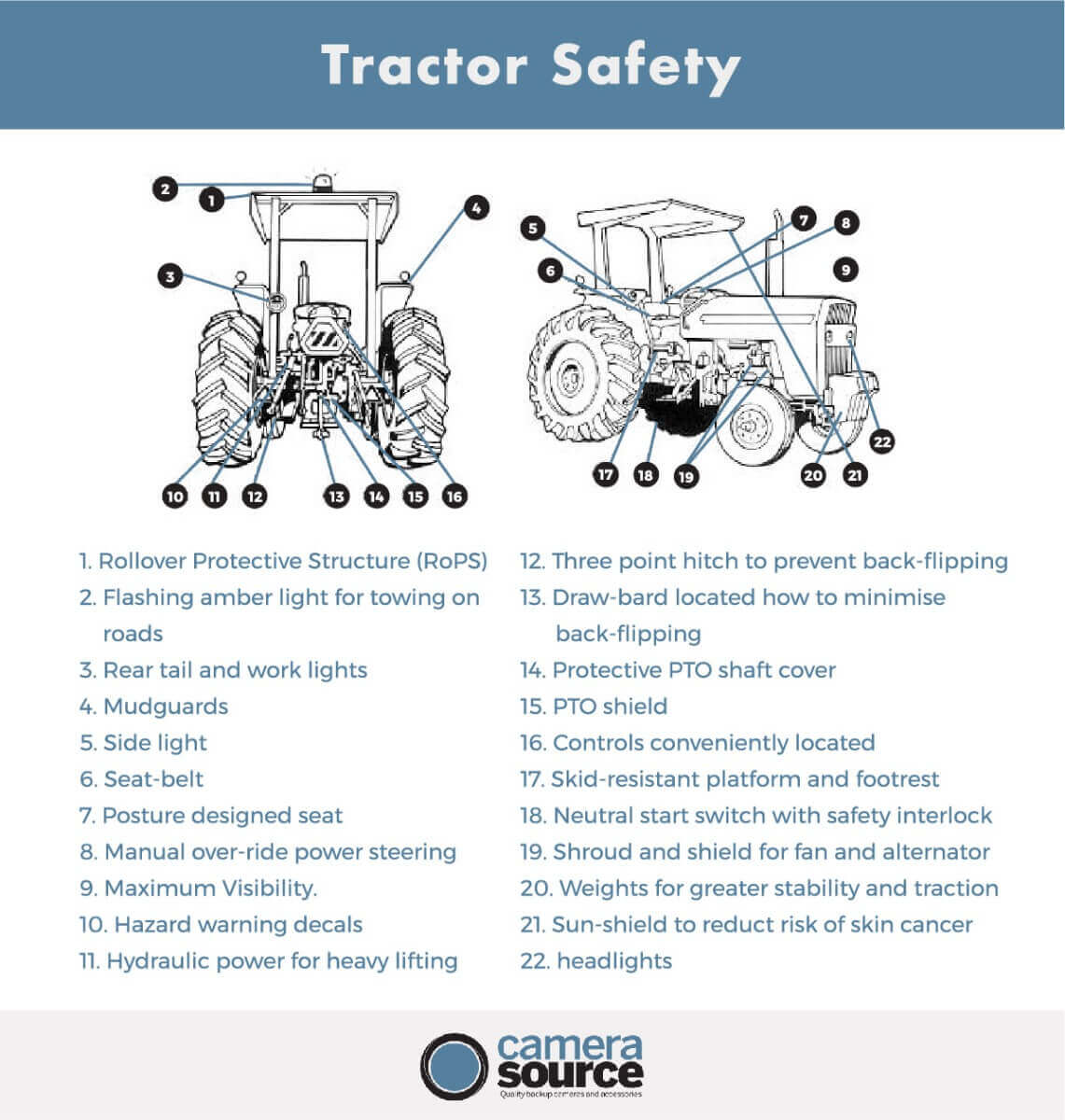

Newer tractors have safety regulations in place that allow them to be sold in the U.S., such as: rollover prevention features, internal warning systems, seat belts, and guard rails. The one modern safety feature that tractors currently lack, but should include, are backup cameras. Significant blind spots are a problem for large trucks, let alone tractors and other farm equipment, prompting the need to install agricultural backup cameras yourself. Fortunately, Camera Source has a huge selection of high quality cameras and accessories.

The Most Common Kinds of Tractor Accidents & Injuries

Some of the most common types of tractor accidents are often similar to automotive accidents. Rollovers, collisions, and entanglement are some of the most common.

Rollover & Overturn Accidents

Tractor rollover, or turnover, accidents cause roughly 130 fatalities each year in the U.S. When a large tractor overturns, the operator can easily sustain serious falling injuries and crushing injuries from the tractor itself.

The most common type of tractor accident is when a tractor rolls over. Tractors are top-heavy, which makes overturn incidents more likely to happen. They can be caused by poor hitching, traveling up a steep incline, holes in the road or field, excessive speed when turning, or driving too close to ditches. Simply put, rollover accidents happen when the tractor is in an unstable situation.

Collisions with Cars

Motor vehicle accidents account for about 50 tractor operator deaths each year. In areas where agricultural workers take tractors and other farm equipment on local roads, these large vehicles can also cause traffic accidents. Tractors do not often work on paved or perfectly level surfaces, which can cause slower speeds and difficulty maneuvering out of the way of traffic.

Entanglement with Moving Parts

About ten people each year suffer fatal injuries from entanglement with tractor equipment, such as internal gears, pulleys, chains, and belts. If a farmer’s hands, feet, or clothing get caught or tangled up in the mechanisms, they can be hurt or killed.

Runover

Some tractors have ignition switches located in areas that are easy to reach from the ground, so farmers may start the vehicle while standing next to it. However, if the tractor starts to move before the farmer can sit in the operating seat, the machine could run over the driver.

Falling or Tipping

Tractor operators ride higher off the ground than most passenger vehicle drivers, causing them to be more susceptible to falling or tipping accidents. Due to their top heavy nature, and instability on paved roads, tractor operators face the risk of falling into animal burrows, sinkholes, or rolling over from uneven terrain that is difficult to see. A driver who experiences a tip-over accident will likely sustain falling injuries upon hitting the ground.

1. Safe Tractor Operation

The safest place for the operator of a tractor is in the operator’s seat, with the safety belt buckled. You can be seriously injured or killed if you attempt to operate a tractor from the ground or another location on the tractor. Remember:

- Only start a tractor from the driver’s seat.

- Never leave the operator’s platform with the engine running.

- Never start a tractor by shorting across the starter terminals. If the tractor is in gear, it will lurch into motion and run over you.

- Do not carry extra riders on heavy machinery, unless it is equipped with a buddy seat. To keep all riders safe, there should only be as many passengers on the tractor as there are seat belts. One tractor seat equals one person.

- There’s no absolutely safe childcare location on a tractor. Accidents can happen, even from cabs with locked doors. Extra riders compromise operator attention to detail and decision-making.

- Operators should use rollover protective structure (ROPS) and a seat belt whenever and wherever applicable.

- Tractors retrofitted with ROPS and seat belts should be professionally installed by an equipment dealer with experience in installations.

- Do not install or build your own ROPS. ROPS are designed and engineered for specific tractor sizes and weights, and are crush-tested to meet industry standards designed to ensure they perform properly in an overturn.

- If your tractor has a foldable ROPS, fold it down only when absolutely necessary, and fold it up and lock it again as soon as possible. Do not wear the seatbelt when the ROPS is folded. Most tractor fatalities are caused by overturns. The safest tractor has a ROPS with enclosed cab.

- Always drive a tractor at a safe speed, especially near populated areas.

- Use special caution on slopes. Slow down for all turns and stay off the highway whenever possible.

2. Prevent Tractor Rollovers & Overturns

Most rollovers result from tractor speed, operator error, or unsafe driving conditions. ROPS do not prevent rollovers from occurring, but in the event of an overturn, ROPS may limit the degree of rollover to 90 degrees.

Rearward toveturns can be prevented by:

- Avoiding driving on steep hillsides

- Backing the tractor up steep hills

- Changing tractor speed gradually by applying power smoothly

- Properly stabilizing the tractor for the work to be done

- Using tire chains, boards and other materials to improve traction of wheels

- Hitching loads to the drawbar correctly

- Always hitch loads at the drawbar, never higher.

- Use front weights to increase tractor stability.

- Don’t change gears on a slope.

- Start forward motion slowly and change speed gradually.

- If possible, avoid backing downhill. It is safest to drive down a hill and back up a hill.

- Drive around ditches rather than through them.

- Back out or be towed out of ditches or mud.

- Keep the front-end loader low when travelling and turning.

- Do not raise the load until you’ve reached the destination and the tractor isn’t moving.

Sideway rollovers can be prevented by:

- Properly stabilizing the tractor

- Avoiding driving on steep hillsides

- Avoiding turning at excessive speeds

- Avoiding driving too close to the edge of roadside ditches or slopes

- Lock the brake pedals together before high-speed road travel.

- Match speed to operating conditions and loads. Operate at low gear and speeds. Do not let the front wheels bounce.

- Slow down before turning.

- Use engine braking when going downhill.

- Avoid crossing steep slopes. Watch for depressions on the downhill side and bumps on the uphill side.

- Turn downhill, not uphill, if stability becomes a problem.

- Keep side-mounted implements on the uphill side of the tractor

- Travel with the front-end loader bucket as low as possible to maintain a low center of gravity.

- If the right front tire goes off the road into the ditch, turn downward or hold steady and slowly recover. Do not attempt to turn sharply back onto the roadway.

3. Tractor Traffic Safety

- Limit mixing tractors and vehicular roadway traffic. When possible, travel at off-peak times.

- If you must be on the road, use clean, highly reflective slow-moving vehicle emblems, turn signals, flashing lights and escort vehicles.

- When possible, pull off and let traffic pass. By motioning another driver to pass around your tractor and equipment, you assume responsibility for their actions.

4. Know Your Tractor & Treat it Right

There’s no excuse for not knowing your tractor, its implements, and how they work.

- Read and understand the Operator's Manual before operating the equipment.

- Be familiar with the safety features of your tractor and any heavy equipment before using.

5. Keep Up with Proper Maintenance & Repairs

When performing maintenance, make sure to block all hydraulic attachments, place controls in neutral and use approved jacks and hoists.Your checklist should include brakes, guards, hazard decals, signals, lights and all other safety devices.

Guided by your operator’s manual, set up a daily maintenance routine to check:

- Engine oil and hydraulic fluid levels

- Radiator coolant level

- Brakes and brake fluid

- Tire pressure

- Fan belts

- ROPS, guards, shields, and seat belt

- Secure and proper connection of implements

6. Wear Appropriate Attire

Loose-fitting clothing is easily caught in the moving parts of tractors and other equipment.

- Wear fitted pants, tuck in any loose shirt tails, and avoid wearing scarves when working on or around machinery.

- Protect your feet by wearing sturdy work shoes or boots with non-skid soles and steel toe caps.

- Heavy work gloves and safety glasses may also be useful when working with machinery.

7. Mount & Dismount the Tractor Safely

Many tractor-related injuries occur as a result of falling while mounting or dismounting the steps of the tractor.

- The steps on the tractor should be used like the steps of a ladder; either two hands and one foot or one hand and two feet should be in contact at all times.

- Be sure your pant cuffs or boot loops are clear of the pedals when you exit the tractor to prevent tripping or falling.

- Take preventive measures to avoid slips, trips and falls. Don’t be in a hurry. Use handholds, steps, and three-point mounting/dismounting procedures.

8. Avoid Bypass Starting

Only start a tractor from the driver’s seat. Avoid starting a tractor or equipment while standing outside the cab or on the ground. An operator who starts a tractor while standing on the ground cannot be sure if the transmission is in neutral or park. When a manual transmission is in gear when the engine is started, the tractor could run over the operator because the tractor will start moving as soon as the engine turns over. If your tractor does not have a shield covering the starter motor, retro-fit shields are available to prevent by-pass starting. This shield should not be removed from the starter motor except when servicing the starter motor, then replaced immediately.

9. Safely Tow Implements

- Fit attachments according to the manufacturer's instructions.

- Always attach implements to the draw bar or the mounting points provided by the manufacturer. Never alter, modify or raise the height of the draw bar unless provided for by the manufacturer.

- Regularly check safety pins on towed lift-wing implements, to ensure they are not worn.

- Always lower the three point linkage and towed implements.

10. Monitor Your Surroundings & Get a Backup Camera

Backup cameras are a standard safety feature in cars, but have yet to be a standard safety feature for tractors and farm equipment— but they should be.

- Whenever you’re driving a tractor, be sure to check your surroundings. You should be sure the area is clear. Children should not be permitted to play where tractors and other machinery are running.

- Be familiar with your terrain and work area.

- Walk the area first to identify any debris or obstacles that could hinder your ability to drive safely.

A backup camera can dramatically enhance your awareness of surroundings when operating a vehicle. That means the risk of accidents is greatly reduced while operating a tractor or other equipment, like ATVs with a backup camera.

Backup cameras can increase ease and safety of driving a tractor in traffic by eliminating blind spots and providing better visibility of their surroundings.

Installing backup cameras on tractors can help the driver identify and avoid collisions with obstacles, and uneven surfaces, bumps, and holes that can cause the tractor to become unstable. This can help prevent:

- Rollovers and overturns

- Runovers

- Collisions

In addition, installing a backup camera can help prevent entanglement with moving parts. Install a camera near parts of machinery to monitor it while running instead of getting off the tractor while it’s running and risk accident and injury. A wireless agricultural backup camera can be installed just about anywhere on the surface of a tractor or equipment that it will fit, so you can safely monitor moving parts from a distance. Some agricultural cameras even come with microphones for enhanced communication and environmental awareness and communication.

Agricultural backup cameras can help perform tasks with accuracy and precisions, like loading and unloading, hitching and towing, and operation of equipment and implements, including but not limited to:

- Box Blade

- Mower/Cutter

- Front End Loader

- Rear Blade

- Post Hole Digger

- Snow Blower

- Land Plane

- Rotary Tiller

- Pallet Fork

- Spreader

- Harrows

- Plows

- Combines

- Sprayers

- Transplanters

- Trailers

- Balers

- Cultivators

- Plastic mulch layers

- Rakes

At Camera Source, we make cameras that can fit any job, no matter how large or small. Our collection of cameras for agricultural use is second to none, and every camera is backed up by our expertise. If you can’t find what you’re looking for, we do custom orders! Start browsing or get in touch with us today.